DepthTouch: Overview

Table of Contents

History

-

2012

-

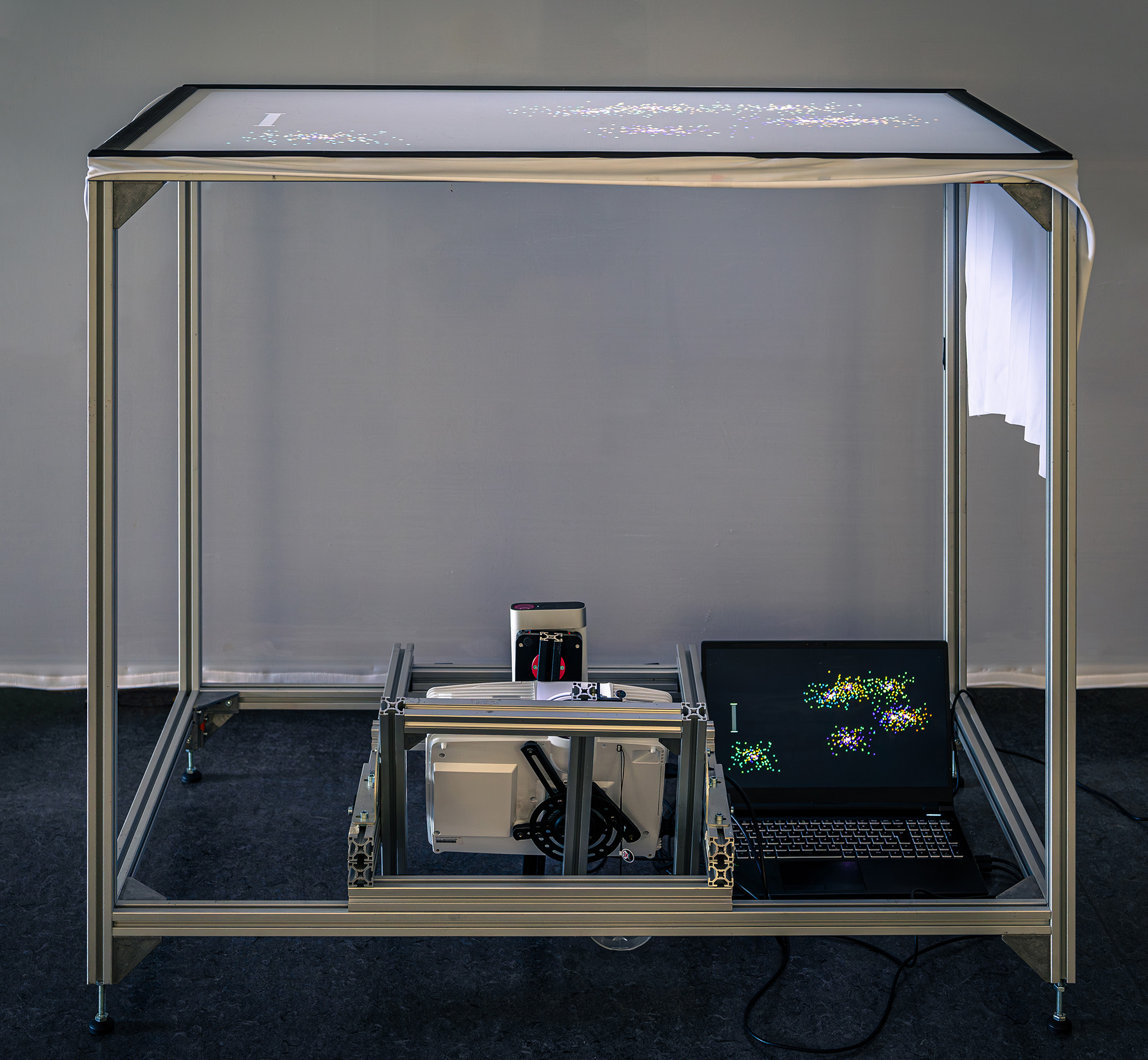

DepthTouch: An Elastic Surface for Tangible ComputingPrototype / Demonstrator

first publication of the system including a demo at the conference | Link

-

-

2013

-

Towards a Design Space for Elastic DisplaysScientific Publication

Advanced design concepts and interaction techniques for Elastic Displays as tabletops

-

-

2018

-

Heinz-Nixdorf Museumsforum, PaderbornInteractive Installation

DepthTouch as part of the museum exhibition featuring three simple visualizations including a mini-game utilizing physics-based interaction metaphors | Link

-

-

2022

-

Usability of Layer-Based Interaction on Elastic DisplaysUser Study

A user study investigating the feasibility and possible limitations of layer-based interaction on an Elastic Displays | Link

-

-

2023

-

Layers App as part of the Lehrwunder project, MagdeburgInteractive Installation

DepthTouch as interactive installation for utilization in educational scenarios

-

DepthTouch@University of Duisburg-EssenInteractive Installation

DepthTouch for interactive scientific data visualization

-

Concept

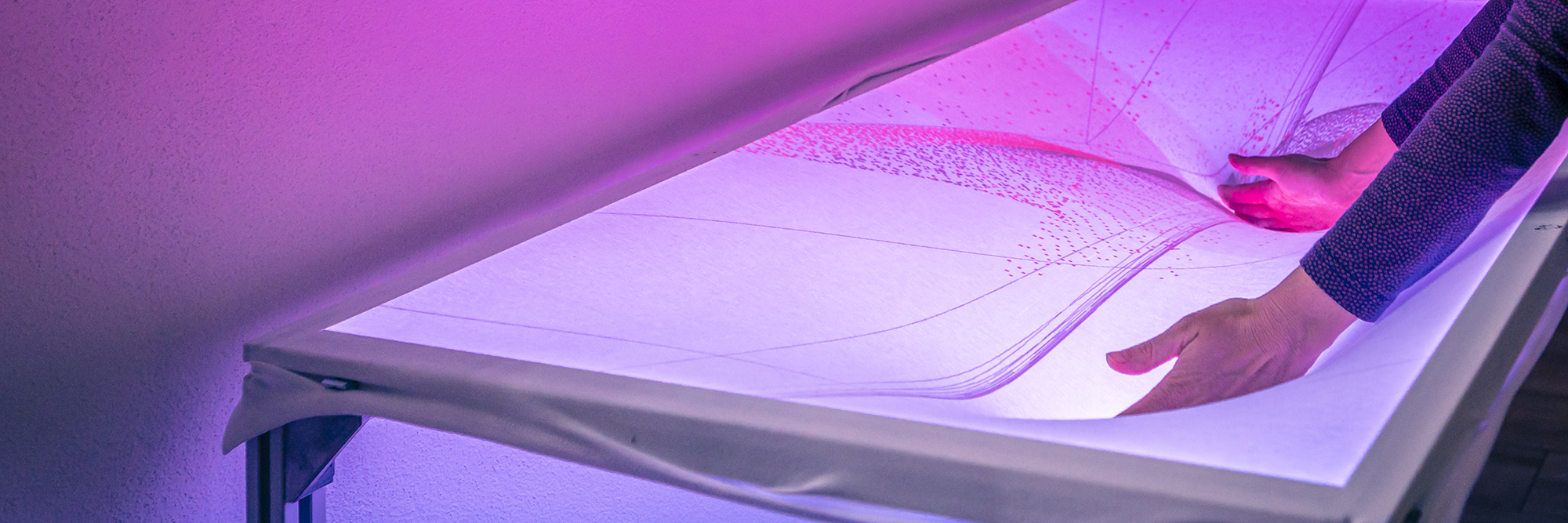

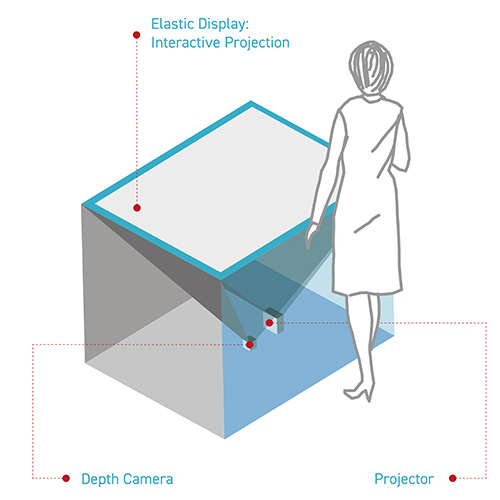

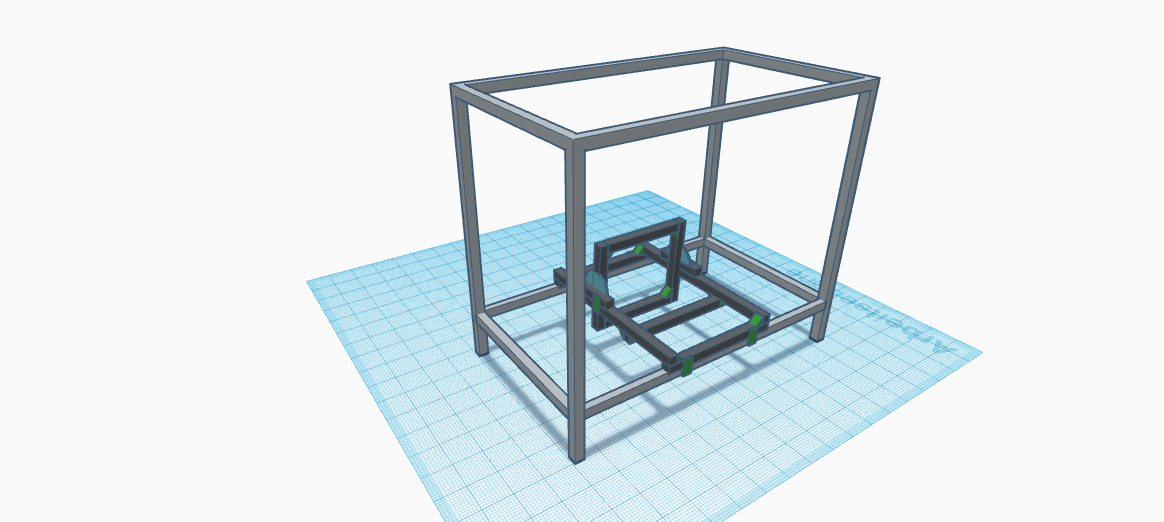

The DepthTouch is an Elastic Display build as a tabletop. The deformable screen is made of an elastic fabric. Usually, Lycra is used, which is a common fabric used for swimsuits and can be purchased in most textile shops.

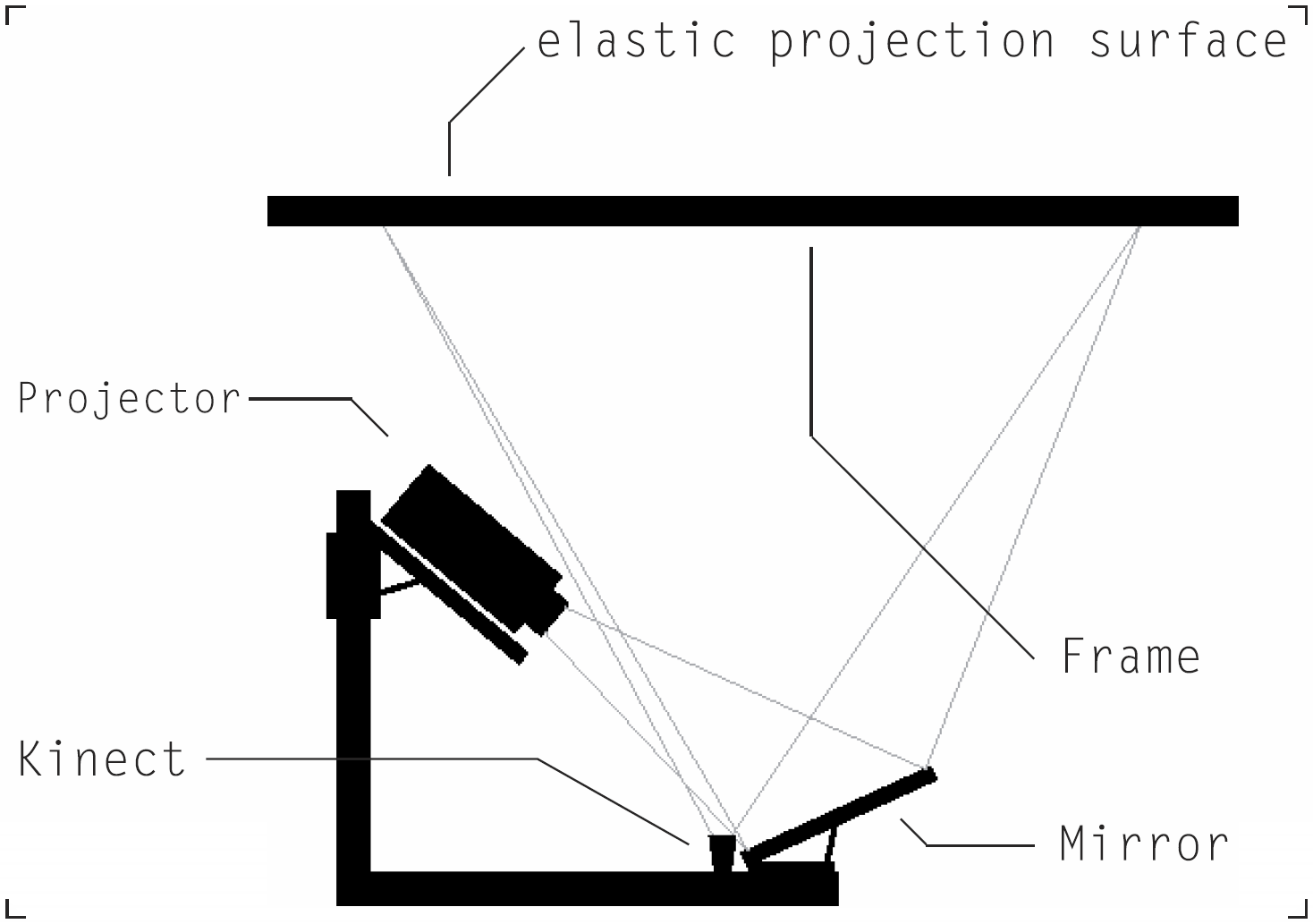

The visualization is generated by a projector underneath the surface via back projection on the fabric. Therefore, the fabric needs to be white and translucent, and the image needs to be mirrored, which is usually done in the projector settings.

Finally, a depth camera which is mounted next to the projector is tracking the deformation of the fabric.

The whole system can be built using consumer hardware and inexpensive aluminium profiles. Based on the experience of the last years, we provide a construction manual including part list and recommended hardware.

Earlier prototypes used a mirror for extending the distance between projector and elastic surface. One issue of this approach is that mirror and projector need to be mounted precisely. Even then, controlling the image distortion was difficult and assembling the table was time-consuming. Furthermore, every vibration or shock applied to the frame when using the tabletop is transmitted to projector and mirror, therefore the image was often “shaky” and often the whole system needed a recalibration.

By using short throw projectors, the tabletop can be constructed without the need for a mirror, which makes adjusting the optical system rather easy and assembling the system is also less time consuming.

Attachment of the fabric

There are different options for attaching the fabric to the frame, however, there are several requirements to meet:

- The fabric needs to be exchanged / washed regularly. Therefore, removing the fabric from the frame should at least not damage the fabric. In the best case changing should be easy and fast to achieve.

- The mounted fabric should have an equal surface tension

- Deforming the screen exerts a lot of force to the fabric. Mounting should be stable enough so that the fabric does not get lose.

During the last years, several option hav been explored:

Velcro straps

Velcro is sewed onto the borders of the fabric and glued onto the aluminium frame.

Advantages

- Changing the fabric is easy

- Velcro can be washed, too

- with strong velcro, the fabric does not get loose

Disadvantages

- Velcro needs to be sewed onto the fabric: exact dimensions necessary, with very stretchy lycra, it is difficult to create an equal surface tension

Clipping into metal frame using rubber coverings

There are rubber coverings that fit into the notch of the aluminium profiles. The fabric can be can be clipped in between.

Advantages

- Changing the fabric is rather easy

- surface tension can be adjusted to individual needs

- the fabric does not get loose

Disadvantages

- low durability: the clipping does mechanically damage the fabric, therefore this option means, that the fabric needs to renewed from time to time

Clipping with an extra frame

An additional frame is mounted on the table, and fixed with screws on the table sides. Additionally, there are rubber coverings on thew parts of the table and the additional frame, that are positioned on top of each other. The fabric is attached between these two rubber covers.

Advantages

- changing the fabric with moderate effort

- surface tension can be adjusted to individual needs

- the fabric does get loose often, but it can be readjusted quite easy

- less mechanical stress on the fabric compared to the previous approach

Disadvantages

- higher build complexity - more complex and heavier construction

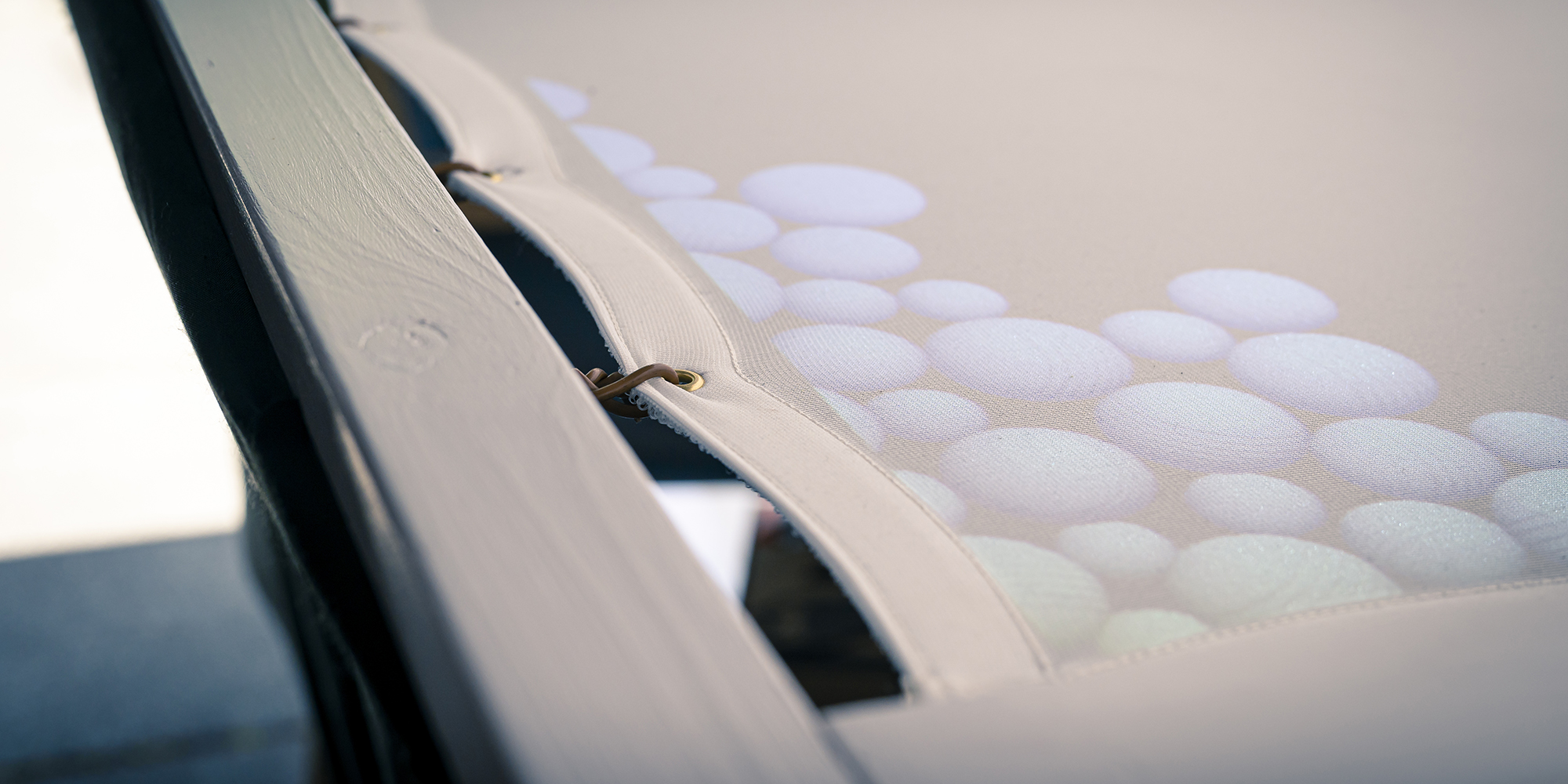

Springs

Comparable to the velcro straps, but this time, springs are used to connect the fabric with the frame

Advantages

- changing the fabric is doable (but takes time)

- the fabric does not get loose

- dynamic attachment of the fabric - interaction towards the borders feels more natural, better distribution of haptioc feedback over the screen area

Disadvantages

- same as with velcro: sewing the borders is not trivial

- higher build complexity for the springs (one-time-effort as the can remain in the frame)

- spring attachment by piercings in the fabric - damage which may lead to tears in the fabric

- differences of the surface tension between the springs (can be compensated with more springs)